Systems Engineering and Electronics ›› 2021, Vol. 43 ›› Issue (8): 2355-2361.doi: 10.12305/j.issn.1001-506X.2021.08.39

• Reliability • Previous Articles Next Articles

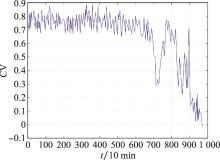

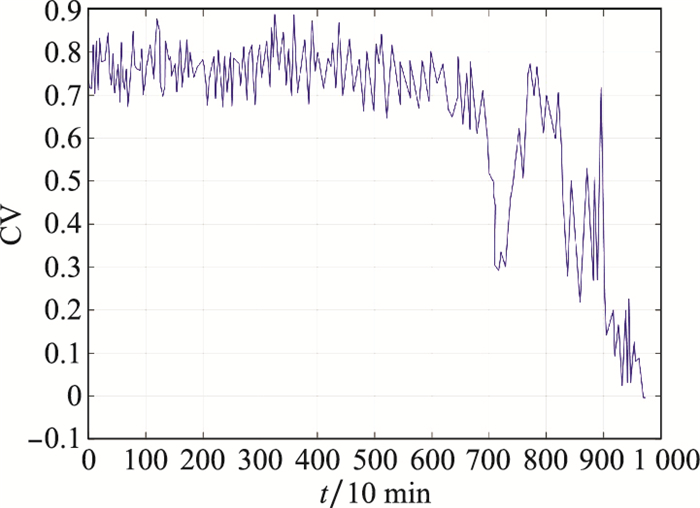

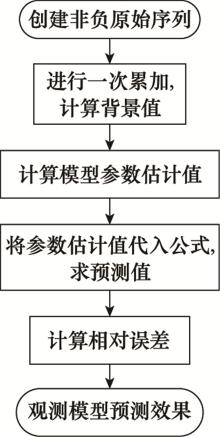

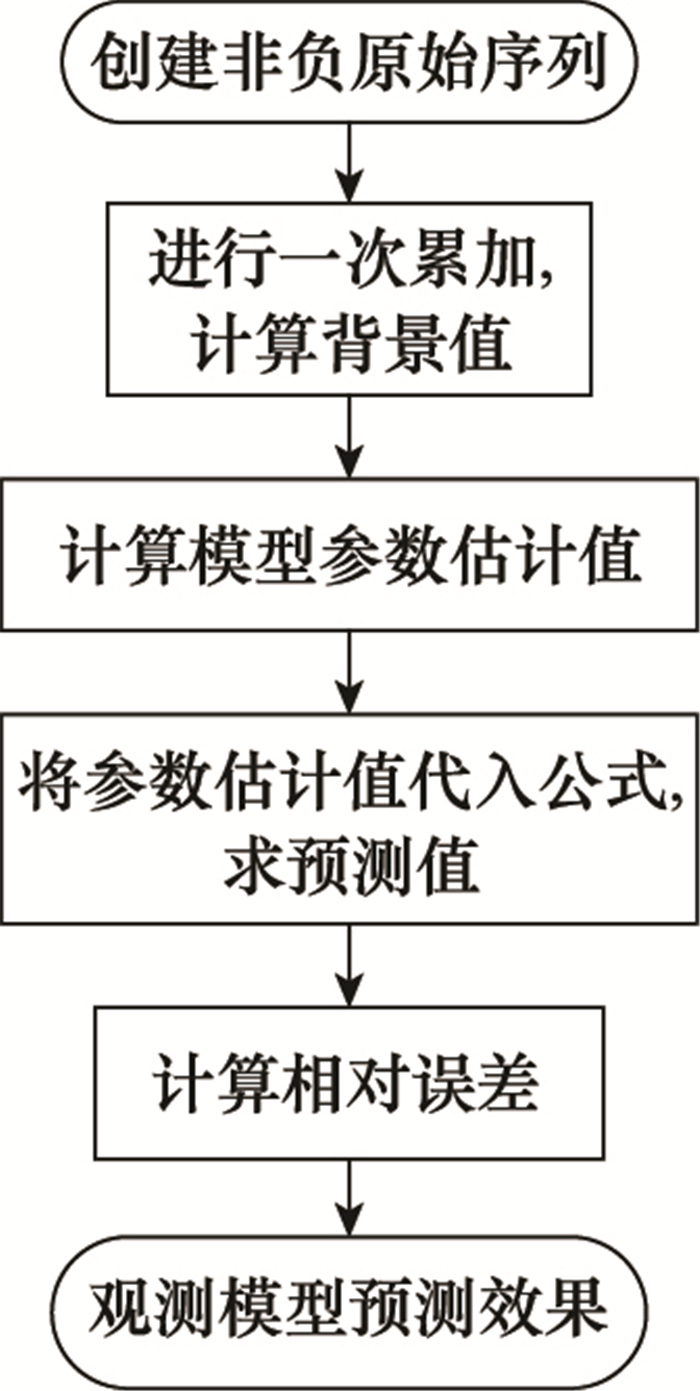

Life prediction of bearings in rotating machinery based on grey model and LSTM network

Tao SHU1, Yichi ZHANG2,*, Rixian DING1

- 1. Air Defense and Missile Defense College, Air Force Engineering University, Xi'an 710051, China

2. Graduate School of Air Force Engineering University, Xi'an 710051, China

-

Received:2020-12-02Online:2021-07-23Published:2021-08-05 -

Contact:Yichi ZHANG

CLC Number:

Cite this article

Tao SHU, Yichi ZHANG, Rixian DING. Life prediction of bearings in rotating machinery based on grey model and LSTM network[J]. Systems Engineering and Electronics, 2021, 43(8): 2355-2361.

share this article

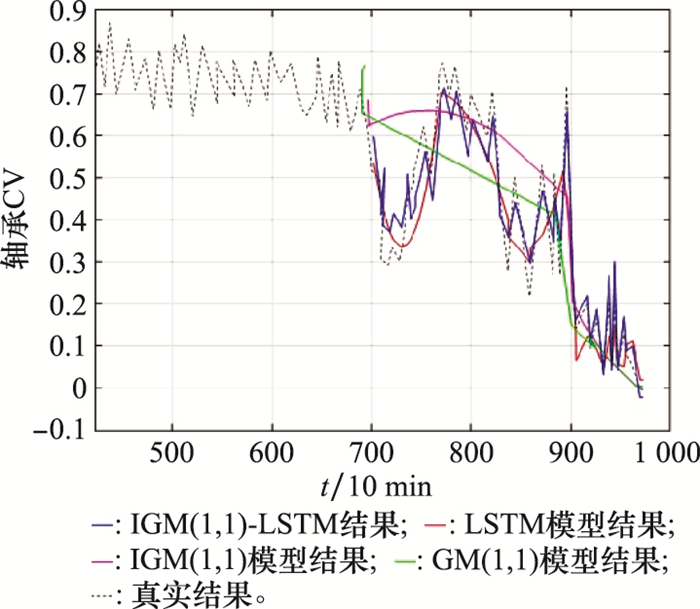

Table 2

Many performance indicators contrast of four models"

| 组别 | IGM-LSTM模型 | GM(1, 1)模型 | IGM(1, 1)模型 | LSTM网络模型 | |||||||||||

| xRMSE | xMAPE/% | P | xRMSE | xMAPE/% | P | xRMSE | xMAPE/% | P | xRMSE | xMAPE/% | P | ||||

| 701~720 | 0.020 | 4.100 | 0.959 | 0.068 | 8.933 | 0.910 | 0.026 | 5.031 | 0.950 | 0.023 | 3.682 | 0.963 | |||

| 721~740 | 0.017 | 4.035 | 0.960 | 0.048 | 7.042 | 0.929 | 0.024 | 5.222 | 0.948 | 0.025 | 3.901 | 0.961 | |||

| 741~760 | 0.019 | 3.781 | 0.962 | 0.044 | 7.563 | 0.924 | 0.030 | 4.184 | 0.958 | 0.022 | 3.632 | 0.964 | |||

| 761~780 | 0.006 | 2.992 | 0.970 | 0.059 | 6.054 | 0.940 | 0.022 | 3.964 | 0.960 | 0.018 | 3.053 | 0.970 | |||

| 781~800 | 0.013 | 2.451 | 0.976 | 0.102 | 9.220 | 0.910 | 0.054 | 5.895 | 0.941 | 0.029 | 4.184 | 0.958 | |||

| 801~820 | 0.015 | 2.867 | 0.971 | 0.086 | 6.763 | 0.932 | 0.032 | 3.313 | 0.967 | 0.015 | 1.999 | 0.980 | |||

| 821~840 | 0.017 | 2.720 | 0.973 | 0.112 | 10.012 | 0.900 | 0.014 | 2.750 | 0.973 | 0.028 | 4.024 | 0.960 | |||

| 841~860 | 0.033 | 3.011 | 0.970 | 0.133 | 11.232 | 0.888 | 0.026 | 3.013 | 0.970 | 0.032 | 3.452 | 0.966 | |||

| 861~880 | 0.024 | 2.053 | 0.980 | 0.097 | 9.441 | 0.910 | 0.034 | 3.562 | 0.964 | 0.028 | 3.563 | 0.964 | |||

| 881~900 | 0.016 | 2.007 | 0.980 | 0.085 | 9.061 | 0.909 | 0.027 | 4.767 | 0.952 | 0.031 | 3.791 | 0.962 | |||

| 901~920 | 0.020 | 1.799 | 0.982 | 0.069 | 8.550 | 0.915 | 0.018 | 2.948 | 0.971 | 0.027 | 3.460 | 0.965 | |||

| 921~940 | 0.025 | 1.391 | 0.986 | 0.072 | 8.354 | 0.917 | 0.023 | 3.754 | 0.963 | 0.020 | 2.772 | 0.972 | |||

| 941~960 | 0.014 | 1.074 | 0.989 | 0.090 | 9.132 | 0.910 | 0.015 | 2.083 | 0.979 | 0.032 | 2.981 | 0.970 | |||

| 961~984 | 0.012 | 1.152 | 0.989 | 0.093 | 7.420 | 0.926 | 0.023 | 2.232 | 0.978 | 0.022 | 2.472 | 0.975 | |||

| AVG | 0.018 | 2.531 | 0.975 | 0.083 | 8.481 | 0.915 | 0.026 | 3.760 | 0.962 | 0.023 | 3.354 | 0.964 | |||

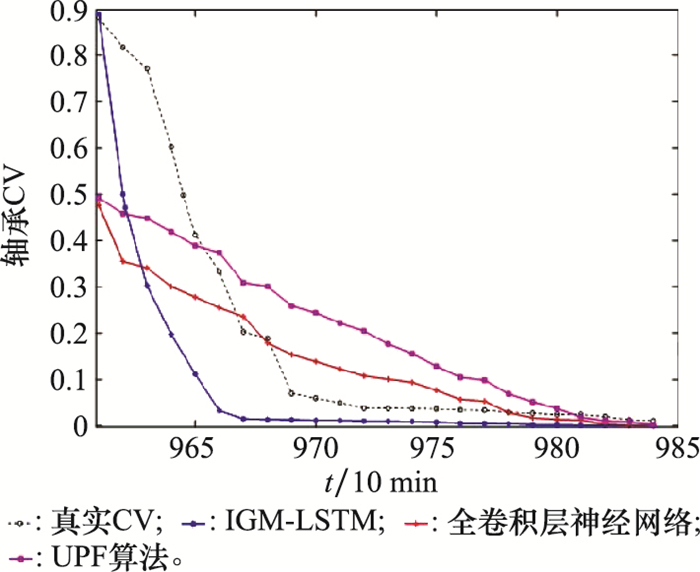

Table 3

Performance indicators comparison of three algorithms at the 20th"

| 阶段 | 全卷积层神经网络 | UPF | IGM-LSTM | |||||

| xMAPE/% | P | xMAPE/% | P | xMAPE/% | P | |||

| 961~968 | 2.214 | 0.978 | 1.883 | 0.981 | 1.496 | 0.985 | ||

| 969~976 | 6.598 | 0.934 | 1.080 | 0.990 | 1.205 | 0.988 | ||

| 977~984 | 4.732 | 0.953 | 3.412 | 0.966 | 0.637 | 0.994 | ||

| AVG | 4.435 | 0.955 | 2.078 | 0.979 | 1.152 | 0.989 | ||

| 1 | 任利娟. 滚动轴承性能退化评估与剩余寿命预测[D]. 济南: 山东大学, 2019. |

| REN L J. Rolling bearing performance degradation assessment and remaining life prediction[D]. Jinan: Shandong university, 2019. | |

| 2 | 郭锐, 赵之谦, 贾鑫龙, 等. 基于ANFIS的外啮合齿轮泵寿命预测研究[J]. 仪器仪表学报, 2020, 41 (1): 223- 232. |

| GUO R , ZHAO Z Q , JIA X L , et al. External gear pump life prediction based on ANFIS study[J]. Journal of Instruments and Meters, 2020, 41 (1): 223- 232. | |

| 3 | 黎慧, 张国文. 基于灰色模型的滚动轴承剩余寿命预测[J]. 机械设计与研究, 2018, 34 (1): 113- 116, 120. |

| LI H , ZHANG G W . Based on grey model to predict the residual life of the rolling bearing[J]. Journal of Mechanical Design and Research, 2018, 6 (1): 113- 116, 120. | |

| 4 | ALI B J , CHEBEL M B , SAIDI L , et al. Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network[J]. Mechanical Systems and Signal Processing, 2015, 56 (8): 150- 172. |

| 5 | 石慧, 曾建潮. 考虑突变状态检测的齿轮实时剩余寿命预测[J]. 振动与冲击, 2017, 36 (21): 173- 184. |

| SHI H , ZENG J C . Considering gear real-time residual life prediction of mutation state detection[J]. Journal of Vibration and Shock, 2017, 36 (21): 173- 184. | |

| 6 | MOHSEN M , MOHAMMAD J S . Bearing remaining useful life prediction under starved lubricating condition using time domain acoustic emission signal processing[J]. Expert Systems with Applications, 2021, 30 (18): 168- 170. |

| 7 |

KHAZAEE M , BANAKAR A , GHOBADIAN B , et al. Remaining useful life (RUL) prediction of internal combustion engine timing belt based on vibration signals and artificial neural network[J]. Neural Computing and Applications, 2020, 20 (4): 16- 20.

doi: 10.1007/s00521-020-05520-3 |

| 8 | 张继冬, 邹益胜, 邓佳林, 等. 基于全卷积层神经网络的轴承剩余寿命预测[J]. 中国机械工程, 2019, 30 (18): 2231- 2235. |

| ZHANG J D , ZOU Y S , DENG J L , et al. Layer based on the convolution of the neural network bearing the residual life prediction[J]. China Mechanical Engineering, 2019, 30 (18): 2231- 2235. | |

| 9 | 文娟, 高宏力. 一种基于UPF的轴承剩余寿命预测方法[J]. 振动与冲击, 2018, 37 (24): 208- 213, 243. |

| WEN J , GAO H L . A bearing residual life prediction method based on UPF[J]. Journal of Vibration and Shock, 2018, 37 (24): 208- 213, 243. | |

| 10 | 刘颉. 基于振动信号分析的旋转机械故障诊断方法研究[D]. 武汉: 华中科技大学, 2018. |

| LIU J. Based on the analysis of vibration signal of rotating machinery fault diagnosis method research[D]. Wuhan: Huazhong University of Science and Technology, 2018. | |

| 11 | 申中杰, 陈雪峰, 何正嘉, 等. 基于相对特征和多变量支持向量机的滚动轴承剩余寿命预测[J]. 机械工程学报, 2016, 49 (2): 183- 189. |

| SHEN Z J , CHEN X F , HE Z J , et al. Characteristics and multivariate support vector machine (SVM) based on relative residual life prediction of the rolling bearing[J]. Journal of Mechanical Engineering, 2016, 49 (2): 183- 189. | |

| 12 | ALI B , MORELLO C . Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network[J]. Mechanical Systems & Signal Processing, 2016, 56 (3): 150- 172. |

| 13 | 张亢, 程军圣, 杨宇. 基于局部均值分解与形态学分形维数的滚动轴承故障诊断方法[J]. 振动与冲击, 2013, 32 (9): 90- 94. |

| ZHANG H , CHENG J S , YANG Y . Credits fractal dimension based on local mean decomposition and form of the rolling bearing fault diagnosis methods[J]. Journal of Vibration and Shock, 2013, 32 (9): 90- 94. | |

| 14 | 周建民, 黎慧, 张龙, 等. 基于EMD和逻辑回归的轴承性能退化评估[J]. 机械设计与研究, 2016, 32 (5): 72- 75, 79. |

| ZHOU J M , LI H , ZHANG L , et al. Bearing performance degradation assessment based on EMD and logistic regression[J]. Journal of Mechanical Design and Research, 2016, 32 (5): 72- 75, 79. | |

| 15 | 钟鑫, 刘文彬, 杨剑锋. 基于逻辑回归的滚动轴承性能退化评估[J]. 科技信息, 2010, 18 (16): 504- 505. |

| ZHONG X , LIU W B , YANG J F . Rolling bearing perfor-mance degradation assessment based on logistic regression[J]. Journal of Information Science and Technology, 2010, 18 (16): 504- 505. | |

| 16 | Bearing data set[EB/OL]. NASA Ames Prognostics data repository[2020-11-04]. http://ti.arc.nasa.gov/tech/dash/poe/prognostic-data-repository. |

| 17 | DING N , LI H L , YIN Z W , et al. Journal bearing seizure degradation assessment and remaining useful life prediction based on long short-term memory neural network[J]. Measurement, 2020, 16 (4): 126- 129. |

| 18 |

SAMUEL V , CHARLES D , JALAL F , et al. The degrees of freedom of partly smooth regularizers[J]. Annals of the Institute of Statistical Mathematics, 2017, 69 (4): 26- 27.

doi: 10.1007/s10463-016-0563-z |

| [1] | Wei FANG, Yu WANG, Wenjun YAN, Chong LIN. Symbolized flight action recognition based on neural network [J]. Systems Engineering and Electronics, 2022, 44(3): 737-745. |

| [2] | Shiyan SUN, Gang ZHANG, Weige LIANG, Bo SHE, Fuqing TIAN. Remaining useful life prediction method of rolling bearing based on time series data augmentation and BLSTM [J]. Systems Engineering and Electronics, 2022, 44(3): 1060-1068. |

| [3] | Chang XI, Zhiming CAI, Jun YUAN. Observer maneuver strategy for leg-by-leg bearing-only tracking [J]. Systems Engineering and Electronics, 2021, 43(9): 2413-2421. |

| [4] | Zhaoli SONG, Xiang JIA, Bo GUO, Zhijun CHENG. Remaining useful life prediction of system based on Bayesian fusion and simulation [J]. Systems Engineering and Electronics, 2021, 43(6): 1706-1713. |

| [5] | Hongli ZHAO, Tianming CHEN, Nie ZHENG. Engine life prediction based on multi-stage similarity of comprehensive index [J]. Systems Engineering and Electronics, 2021, 43(5): 1430-1436. |

| [6] | Chuang CHEN, Ningyun LU, Bin JIANG, Yin XING. Optimization of condition-based maintenance strategy for single-unit accelerated degrading systems [J]. Systems Engineering and Electronics, 2020, 42(3): 613-619. |

| [7] | Kui HUANG, Chun SU. Failure prediction based on combined model of grey neural network [J]. Systems Engineering and Electronics, 2020, 42(1): 238-244. |

| [8] | Gang ZHANG, Fuqing TIAN, Weige LIANG, Bo SHE. Construction method of bearing health indicator based on multi-scale AlexNet network [J]. Systems Engineering and Electronics, 2020, 42(1): 245-252. |

| [9] | BAI Can, HU Changhua, SI Xiaosheng, LI Hongpeng, ZHANG Zhengxin, PEI Hong. Remaining useful life prediction method for degradation equipment with random shocks#br# [J]. Systems Engineering and Electronics, 2018, 40(12): 2729-2735. |

| [10] | LIU Yanfang, LIU Xingfu, QI Naiming. Hardware in loop simulation platform with super low disturbance torque for attitude control system of micro- and nano-satellites [J]. Systems Engineering and Electronics, 2017, 39(8): 1808-1814. |

| [11] | GUAN Xin, GUAN Xin, TAO Li, YI Xiao. Unbiased algorithm of multiple platform passive location based on sliding window [J]. Systems Engineering and Electronics, 2016, 38(9): 1981-1986. |

| [12] | HUANG Cheng, WANG Yan, CHEN Xinglin. Relative attitude and position control for rendezvous and docking#br# based on airbearing tables [J]. Systems Engineering and Electronics, 2016, 38(12): 2814-2820. |

| [13] | CHEN Jun, PENG Xiao-qi, TANG Xiu-ming, SONG Yan-po, LIU Zheng. Error correction method for support vector regression [J]. Systems Engineering and Electronics, 2015, 37(8): 1832-1836. |

| [14] | XU Zheyao, QI Naiming, SUN Qilong, WANG Tianye. Automatic mass balancing of threeaxis rotational spacecraft simulator [J]. Systems Engineering and Electronics, 2015, 37(5): 1124-1132. |

| [15] | ZHAO Jian-zhong, XU Ting-xue, YE Wen, ZHANG Lei. Missile equipment fault forecast based on data fusion and improved MUGM(1,m,w) [J]. Systems Engineering and Electronics, 2015, 37(4): 832-837. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||