Systems Engineering and Electronics ›› 2023, Vol. 45 ›› Issue (3): 931-940.doi: 10.12305/j.issn.1001-506X.2023.03.35

• Reliability • Previous Articles

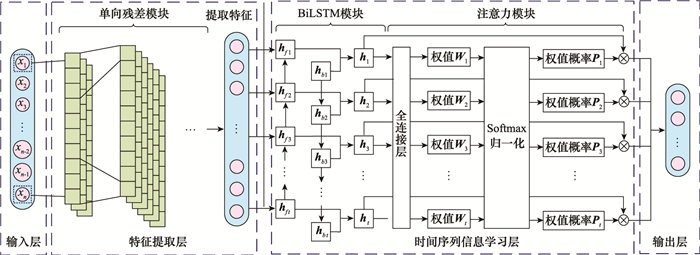

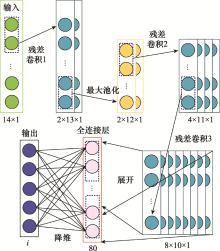

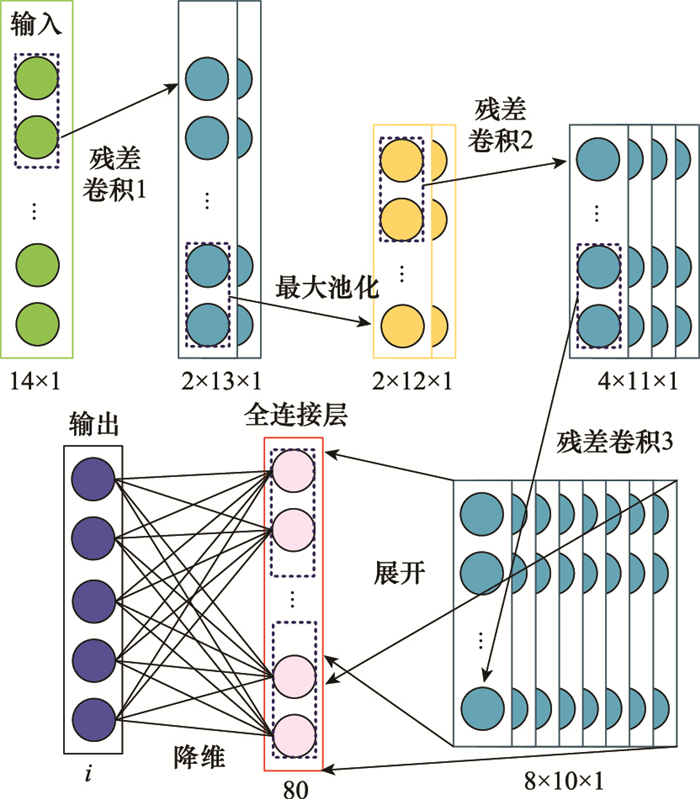

Prediction method for mechanical equipment based on RCNN-ABiLSTM

Xiaojia YAN1, Weige LIANG1,*, Gang ZHANG2, Bo SHE1, Fuqing TIAN1

- 1. College of Weaponry Engineering, Naval University of Engineering, Wuhan 430033, China

2. College of Missiles and Naval Guns, Dalian Naval Academy, Dalian 116016, China

-

Received:2022-01-20Online:2023-02-25Published:2023-03-09 -

Contact:Weige LIANG

CLC Number:

Cite this article

Xiaojia YAN, Weige LIANG, Gang ZHANG, Bo SHE, Fuqing TIAN. Prediction method for mechanical equipment based on RCNN-ABiLSTM[J]. Systems Engineering and Electronics, 2023, 45(3): 931-940.

share this article

Table 3

Comparing the results of different forecasting models"

| 方法 | FD001 | FD002 | FD003 | FD004 | ||||||||

| RMSE | Score | RMSE | Score | RMSE | Score | RMSE | Score | |||||

| SVR[ | 20.96 | 1 382 | 35.96 | 18 900 | 21.64 | 2 956 | 36.54 | 10 023 | ||||

| CNN[ | 18.45 | 1 290 | 30.29 | 13 600 | 19.82 | 1 600 | 29.16 | 7 890 | ||||

| LSTM[ | 16.14 | 338 | 24.49 | 4 450 | 16.18 | 852 | 28.17 | 5 550 | ||||

| CNN-LSTM[ | 16.13 | 303 | 20.46 | 3 440 | 17.12 | 1 420 | 23.26 | 4 630 | ||||

| Autoencoder-BiLSTM[ | 13.63 | 261 | 19.32 | 3 560 | 14.21 | 285 | 22.45 | 4 886 | ||||

| RCNN-ABiLSTM | 12.98 | 258 | 19.16 | 2 980 | 13.24 | 246 | 22.29 | 3 795 | ||||

Table 3

| 1 | SAIDI L , BENBOUZID M . Prognostics and health management of renewable energy systems: state of the art review, challenges, and trends[J]. Electronics, 2021, 10 (22): 27- 32. |

| 2 |

CHENG C , MA G J , ZHANG Y , et al. A deep learning-based remaining useful life prediction approach for bearings[J]. IEEE/ASME Trans.on Mechatronics, 2020, 25 (3): 1243- 1254.

doi: 10.1109/TMECH.2020.2971503 |

| 3 | GUO R X , WANG Y , ZHANG H C , et al. Remaining useful life prediction for rolling bearings using EMD-RISI-LSTM[J]. IEEE Trans.on Instrumentation and Measurement, 2021, 70, 3509812. |

| 4 | YU W , KIM I Y , MECHEFSKE C . Remaining useful life estimation using a bidirectional recurrent neural network based autoencoder scheme[J]. Mechanical Systems and Signal Processing, 2019, 129 (15): 764- 780. |

| 5 | CUBILLO A , VERMEULEN J , RODRIGUEZ D L P M , et al. Physics-based integrated vehicle health management system for predicting the remaining useful life of an aircraft planetary gear transmission[J]. International Journal of Structural Integrity, 2017, 8 (4): 17- 35. |

| 6 | FAN Z L , LIU G B , SI X S , et al. Degradation data-driven approach for remaining useful life estimation[J]. Systems Engineering and Electronics, 2013, 1 (10): 173- 182. |

| 7 | LI Y X , HUANG X Z , DING P F , et al. Wiener-based remaining useful life prediction of rolling bearings using improved Kalman filtering and adaptive modification[J]. Measurement, 2021, 18 (2): 10- 16. |

| 8 | 黄亮, 刘君强, 贡英杰. 基于Wiener过程的发动机多阶段剩余寿命预测[J]. 北京航空航天大学学报, 2018, 44 (5): 1081- 1087. |

| HUANG L , LIU J Q , GONG Y J . Multi-stage remaining life prediction of engine based on Wiener process[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44 (5): 1081- 1087. | |

| 9 | 袁庆洋, 叶建华, 李晓钢. BLDC电机温度退化多段Wiener过程建模[J]. 北京航空航天大学学报, 2018, 44 (7): 1514- 1519. |

| YUAN Q Y , YE J H , LI X G . Multi-stage Wiener process modeling for temperature degradation of BLDC motors[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44 (7): 1514- 1519. | |

| 10 | 冯磊, 王宏力, 司小胜, 等. 基于半随机滤波-期望最大化算法的剩余寿命在线预测[J]. 航空学报, 2015, 36 (2): 555- 563. |

| FENG L , WANG H L , SI X S , et al. Online prediction of remaining life based on semi-random filtering-expectation-maximization algorithm[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36 (2): 555- 563. | |

| 11 | KUNDU P , DARPE A K , KULKARNI M S . Weibull accelerated failure time regression model for remaining useful life prediction of bearing working under multiple operating conditions[J]. Mechanical Systems and Signal Processing, 2019, 134 (1): 106302. |

| 12 | ZHANG Y B , JIA Y X , FENG T L , et al. Remaining useful life prediction model of planetary carrier in helicopter main gear-box based on Gamma degradation process[J]. Journal of Vibration and Shock, 2012, 31 (14): 47- 51. |

| 13 | 王泽洲, 陈云翔, 蔡忠义, 等. 基于比例关系加速退化建模的设备剩余寿命在线预测[J]. 系统工程与电子技术, 2021, 43 (2): 584- 592. |

| WANG Z Z , CHEN Y X , CAI Z Y , et al. Equipment remaining useful lifetime online prediction based on accelerated degradation modeling with the proportion relationship[J]. Systems Engineering and Electronics, 2021, 43 (2): 584- 592. | |

| 14 | WU M H , WANG X M , LIU X Z . On condition maintenance model for complex electromechanical equipments based on remaining useful life and Wiener process[J]. Journal of Physics Conference Series, 2020, 16 (78): 12- 14. |

| 15 | BABU G S, ZHAO P, LI X L. Deep convolutional neural network based regression approach for estimation of remaining useful life[C]//Proc. of the International Conference on Database Systems for Advanced Applications, 2016: 214-228. |

| 16 | HOCHREITER S , SCHMIDHUBER J , et al. Long short-term memory[J]. Neural Computation, 1997, 9 (8): 1735- 1780. |

| 17 | ZHENG S A, RISTOVSKI K, FARAHAT A, et al. Long short-term memory network for remaining useful life estimation[C]//Proc. of the IEEE International Conference on Prognostics and Health Management, 2017. |

| 18 | 王鑫, 吴际, 刘超, 等. 基于LSTM循环神经网络的故障时间序列预测[J]. 北京航空航天大学学报, 2018, 44 (4): 772- 784. |

| WANG X , WU J , LIU C , et al. Fault time series prediction based on LSTM recurrent neural network[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44 (4): 772- 784. | |

| 19 | XIANG S , QIN Y , LUO J , et al. Multicellular LSTM-based deep learning model for aero-engine remaining useful life prediction[J]. Reliability Engineering & System Safety, 2021, 216, 107927. |

| 20 | 宋亚, 夏唐斌, 郑宇, 等. 基于Autoencoder-BLSTM的涡扇发动机剩余寿命预测[J]. 计算机集成制造系统, 2019, 25 (7): 1611- 1619. |

| SONG Y , XIA T B , ZHENG Y , et al. Prediction of remaining life of turbofan engine based on Autoencoder-BLSTM[J]. Computer Integrated Manufacturing System, 2019, 25 (7): 1611- 1619. | |

| 21 | 孙世岩, 张钢, 梁伟阁, 等. 基于时间序列数据扩增和BLSTM的滚动轴承剩余寿命预测方法[J]. 系统工程与电子技术, 2022, 44 (3): 1060- 1068. |

| SUN S Y , ZHANG G , LIANG W G , et al. Remaining useful life prediction method of rolling bearing based on time series data augmentation and BLSTM[J]. Systems Engineering and Electronics, 2022, 44 (3): 1060- 1068. | |

| 22 | CHEN J G , CHEN D J , LIU G P . Using temporal convolution network for remaining useful lifetime prediction[J]. Engineering Reports, 2020, 3 (3): 12305. |

| 23 | KUO P H , HUANG C J . A high precision artificial neural networks model for short-term energy load forecasting[J]. Energies, 2018, 11 (1): 213- 226. |

| 24 | YAO D C , LI B Y , LIU H C , et al. Remaining useful life prediction of roller bearings based on improved 1D-CNN and simple recurrent unit[J]. Measurement, 2021, 175 (4): 10- 16. |

| 25 | 李永刚, 王朝晖, 万晓依, 等. 基于深度残差双单向DLSTM的时空一致视频事件识别[J]. 计算机学报, 2018, 41 (12): 2852- 2866. |

| LI Y G , WANG C H , WAN X Y , et al. Spatiotemporally consistent video event recognition based on deep residual dual unidirectional DLSTM[J]. Chinese Journal of Computers, 2018, 41 (12): 2852- 2866. | |

| 26 | HE K M, ZHANG X Y, REN S Q, et al. Deep residual learning for image recognition[C]//Proc. of the IEEE Conference on Computer vision, 2016: 770-778. |

| 27 | MA X L , TAO Z M , WANG Y H , et al. Long short-term memory neural network for traffic speed prediction using remote microwave sensor data[J]. Transportation Research Part C: Emerging Technologies, 2015, 54, 187- 197. |

| 28 | SAXENA A, KAI G, SIMON D, et al. Damage propagation modeling for aircraft engine run-to-failure simulation[C]//Proc. of the International Conference on Prognostics and Health Management, 2008. |

| 29 | HEIMES F O. Recurrent neural networks for remaining useful life estimation[C]//Proc. of the International Conference on Prognostics and Health Management, 2008. |

| 30 | KONG Z M , CUI Y D , XIA Z , et al. Convolution and long short-term memory hybrid deep neural networks for remaining useful life prognostics[J]. Applied Sciences, 2019, 9 (19): 41- 56. |

| [1] | Qingyuan ZHAO, Zhiqiang ZHAO, Chunmao YE, Yaobing LU. Micro-motion fusion recognition of double band early warning radar based on self-attention mechanism [J]. Systems Engineering and Electronics, 2023, 45(3): 708-716. |

| [2] | Pengyu CAO, Chengzhi YANG, Zesheng CHEN, Lu WANG, Limeng SHI. Radar signal recognition method based on deep residual shrinkage attention network [J]. Systems Engineering and Electronics, 2023, 45(3): 717-725. |

| [3] | Xiao HAN, Shiwen CHEN, Meng CHEN, Jincheng YANG. Open-set recognition of LPI radar signal based on reciprocal point learning [J]. Systems Engineering and Electronics, 2022, 44(9): 2752-2759. |

| [4] | Pingliang XU, Yaqi CUI, Wei XIONG, Zhenyu XIONG, Xiangqi GU. Generative track segment consecutive association method [J]. Systems Engineering and Electronics, 2022, 44(5): 1543-1552. |

| [5] | Tao WU, Lunwen WANG, Jingcheng ZHU. Camouflage image segmentation based on transfer learning and attention mechanism [J]. Systems Engineering and Electronics, 2022, 44(2): 376-384. |

| [6] | Tao JIN, Xiaofeng WANG, Runlan TIAN, Xindong ZHANG. Rapid recognition method of radar emitter based on improved 1DCNN+TCN [J]. Systems Engineering and Electronics, 2022, 44(2): 463-469. |

| [7] | Yutang MA, Peng SUN, Jieyong ZHANG, Peng WANG, Yunfei YAN, Liang ZHAO. Air group intention recognition method under imbalance samples [J]. Systems Engineering and Electronics, 2022, 44(12): 3747-3755. |

| [8] | Yiqiang TANG, Xiaopeng YANG, Shengming ZHU. Low-orbit satellite channel prediction algorithm based on the hybrid CNN-BiLSTM using attention mechanism [J]. Systems Engineering and Electronics, 2022, 44(12): 3863-3870. |

| [9] | Yongxing GAO, Xudong WANG, Ling WANG, Daiyin ZHU, Jun GUO, Fanwang MENG. Weather signal detection for dual polarization weather radar based on RCNN [J]. Systems Engineering and Electronics, 2022, 44(11): 3380-3387. |

| [10] | Lingzhi QU, Junan YANG, Hui LIU, Keju HUANG. Method for individual identification of communication radiation source embedded in attention mechanism [J]. Systems Engineering and Electronics, 2022, 44(1): 20-27. |

| [11] | Ziyan LIU, Shanshan MA, Jing LIANG, Mingcheng ZHU, Lei YUAN. Attention mechanism based CNN channel estimation algorithm in millimeter-wave massive MIMO system [J]. Systems Engineering and Electronics, 2022, 44(1): 307-312. |

| [12] | Bangyan CUI, Runlan TIAN, Dongfeng WANG, Gang CUI, Jingyuan SHI. Radar emitter identification based on attention mechanism and improved CLDNN [J]. Systems Engineering and Electronics, 2021, 43(5): 1224-1231. |

| [13] | Shiyang GAO, Huixu DONG, Runlan TIAN, Xindong ZHANG. Radar emitter signal recognition method based on SRNN+Attention+CNN [J]. Systems Engineering and Electronics, 2021, 43(12): 3502-3509. |

| [14] | Ruochen ZHAO, Jingdong WANG, Siyu LIN, Dongze GU. Small building detection algorithm based on convolutional neural network [J]. Systems Engineering and Electronics, 2021, 43(11): 3098-3106. |

| [15] | Guangshuai LI, Juan SU, Yihong LI, Xiang LI. Aircraft detection in SAR images based on convolutional neural network and attention mechanism [J]. Systems Engineering and Electronics, 2021, 43(11): 3202-3210. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||